F51 Urban Sports Park, Folkestone

- Home

- Case Studies

- F51 Urban Sports Park

Cambian Role:

Skatepark Design, Detailed Design, Off-site Production, Installation

Project Team:

Architects: Guy Hollaway || Engineer: Ramboll || Main Contractor: Jenner Group

The world’s first purpose built multi-storey skatepark features two large wooden designs. Cambian assisted the Design Team throughout the project, and then designed and installed the two complex modular plywood structures.

A Carpark, Evolved

F51 is a unique piece of architecture conceived by Guy Holloway Architects, originally planned to be a multi-storey car park. Throughout it’s early design evolution, one level at a time it transformed into the award winning building which opened in 2022. The mixed use facility incorporates three floors of skatepark, climbing and bouldering, and a home for the local boxing club.

Made possible with the support of The Roger De Haan Charitable Trust these often marginalised sports are brought to a town centre location, in one of the South Coast’s most up and coming towns, Folkestone.

2 Levels of Contrasting Geometry

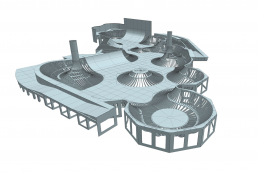

Cambian joined the project team in 2016 and completed the architectural design for two floors of skatepark. The complex and highly constrained building steered the designs towards the two unique and contrasting layouts.

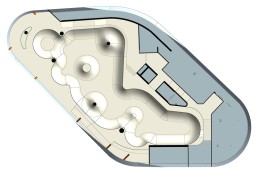

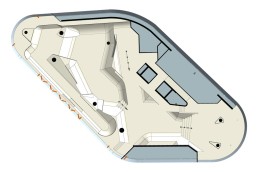

On the third level, the flow floor is a continuous undulating compound curved geometry where skaters can navigate the space in a smooth continuous line.

On the second level, the street floor takes it’s inspiration from faceted structures more commonly found in the built environment.

Managing Interactions

The construction programme required off-site production of the modular plywood structure to be concurrent with superstructure and façade. This requirement, along with the complex and constrained nature of the building, required careful management of the design for installation.

To achieve this, Cambian developed a comprehensive model of the intended arrangement, embedding detailed designs from the steel fabricators, formwork contractors and façade engineers. The detailed design for the plywood structure was driven from these, but then once available updated based on as-built 3D scan data. The modules which interacted with these constraints were then updated automatically, and released to production.

Design Intent Re-Use

To create the CAD model for the 10,000’s of unique components, Cambian developed a fundamentally novel method of working, extensively leveraging the functionality of Siemens NX.

Initially, the overall form, or reference part, is subdivided into modules, each of which destined to become a single plywood structure. The detailed design for a number of fundamentally different modules was then created, complete with all joint details and fixing holes. These seed modules were then propagated to other vaguely similar sections, through a technique that was able to cater for changes in form far exceeding that possible with normal parametric or scripted methods, hence saving 100’s of hours of CAD time.

Surface Approximation

Both floors are finished in a continuous skin of 6mm Birch plywood. Larger simple areas are covered in a herringbone pattern, similar to a large parquet floor, with panel seams diagonally positioned for a smoother result. The more complex areas, commonly being of irrational geometry, are covered in numerous smaller and commonly unique components.

Cambian developed a CAD based system for discretisation of these surfaces to individual components, which are developed to flat to enable CNC cutting from panels. Our automated CAM processing of these parts then includes machined engraving part ID’s onto the reverse face, whilst countersinking the visible side.

The resultant approximation requires skilled fitting, with the dense screw pattern being used to incrementally force the ply to adopt the underlying form. Once installed, a very smooth surface is created, with the patterns beautifully following the form.