Qatari Embassy, Brussels

- Home

- Case Studies

- Qatari Embassy, Brussels

Cambian Role:

Geometry Optimisation, GRG Mould Tooling

Project Team:

Architects: Jaspers-Eyers Architects || GRG Supplier: Design & Visual Concepts

The central atrium of the Qatari Embassy in Brussels features an impressive faceted dome. Cambian assisted on the project with geometry optimisation, modulation and production of mould tooling for the GRG sections.

Faceted GRG Dome

The central atrium of the Qatari Embassy in Brussels features a stunning dome formed from glass reinforced gypsum (GRG).

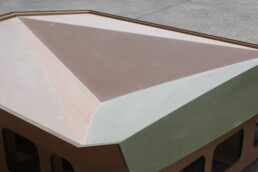

The base of the dome is 12m diameter, and rises more than 4m to the central ocular approximately 14.5m above floor level. The lowest face of the dome is a continuous conical face, above which faceted planar surfaces of kite and triangular faces diminish towards the centre.

The GRG, which provides the decorative finish to the interior, is suspended from pre-cast reinforced concrete structural segments which form the roof to the dome.

Cambian optimised the geometry and, working with the GRG supplier, developed a modulated system for installation. Each of the 16 repeating radial segments was subdivided into three sections of approximately equal surface area. The split locations were chosen to the nearest rational point within the faceted geometry for ease of hand-tooling on site. The joints were also oriented on common horizonal planes to facilitate setting out during installation.

Each of the radial joints were designed to facilitate installation, where access was only possible to the reverse of one edge of the cast components. At the accessible edge, the hangers were deployed for suspension from the dome, the other side used a concealed joint to support the cast from it’s neighbour.

GRG Mould Tooling

The GRG sections were produced from a fabricated MR MDF mould, including the curved conical section. The high precision framework was detailed to ensure accurate positioning of the face panels, hence providing crisp groins and mitres in the GRG casts. The moulds were surfaced in Polyester, providing an excellent quality finish, and durability exceeding the 16 lifts required.

Demountable edge trimming components were provided to control cast thickness and to mould the concealed fixing details.

This method of mould production offers an economical solution vs traditional workshop builds, with the added benefit of mobility to keep bench space free in the GRG production facility.