FLOW Bridge

- Home

- Case Studies

- FLOW Bridge

Cambian Role:

Geometry Optimisation, GRP Mould Tooling

Project Team:

Architects: Knight Architects || GRP Laminator: SuiGeneris

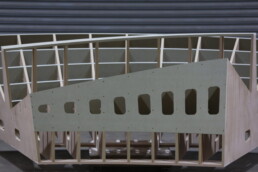

Network Rail’s pioneering off-site GRP rail footbridge, FLOW bridge. Cambian assisted with geometry optimisation, and production of mould tooling for the GRP hull modules.

Innovative Rail Footbridge

The FLOW bridge is a product based approach to pedestrian rail crossings which provides an alternative to the existing heavy steel design commonly used in the UK.

The modular system, produced largely from fibre-reinforced polymers (FRP), is designed for off-site production and swift installation on concrete free foundations.

The design incorporates a ‘spine’ which is installed first, following this, the modular ‘hull’ sections are craned into place.

Cambian produced the direct lift tooling for the GRP hull sections for the prototype installation.

Direct Lift GRP Tooling

For the prototype installation, Cambian fabricated modular sections of direct lift tooling from a combination of MDF and plywood panels, finished in Polyester primer.

The complex, re-entrant geometry at the spine interface and glass parapet attachment points required multiple demountable sections within each mould.

Each helical GRP module was produced from two sections of mould, split to facilitate transport. Three straight moulds were produced, the combination of which enabled production of the varying straight lengths required.